Current Steelcase Work

2023 - Present

I’ve been a product engineer on the worksurfaces & storage team at Steelcase for two and a half years.

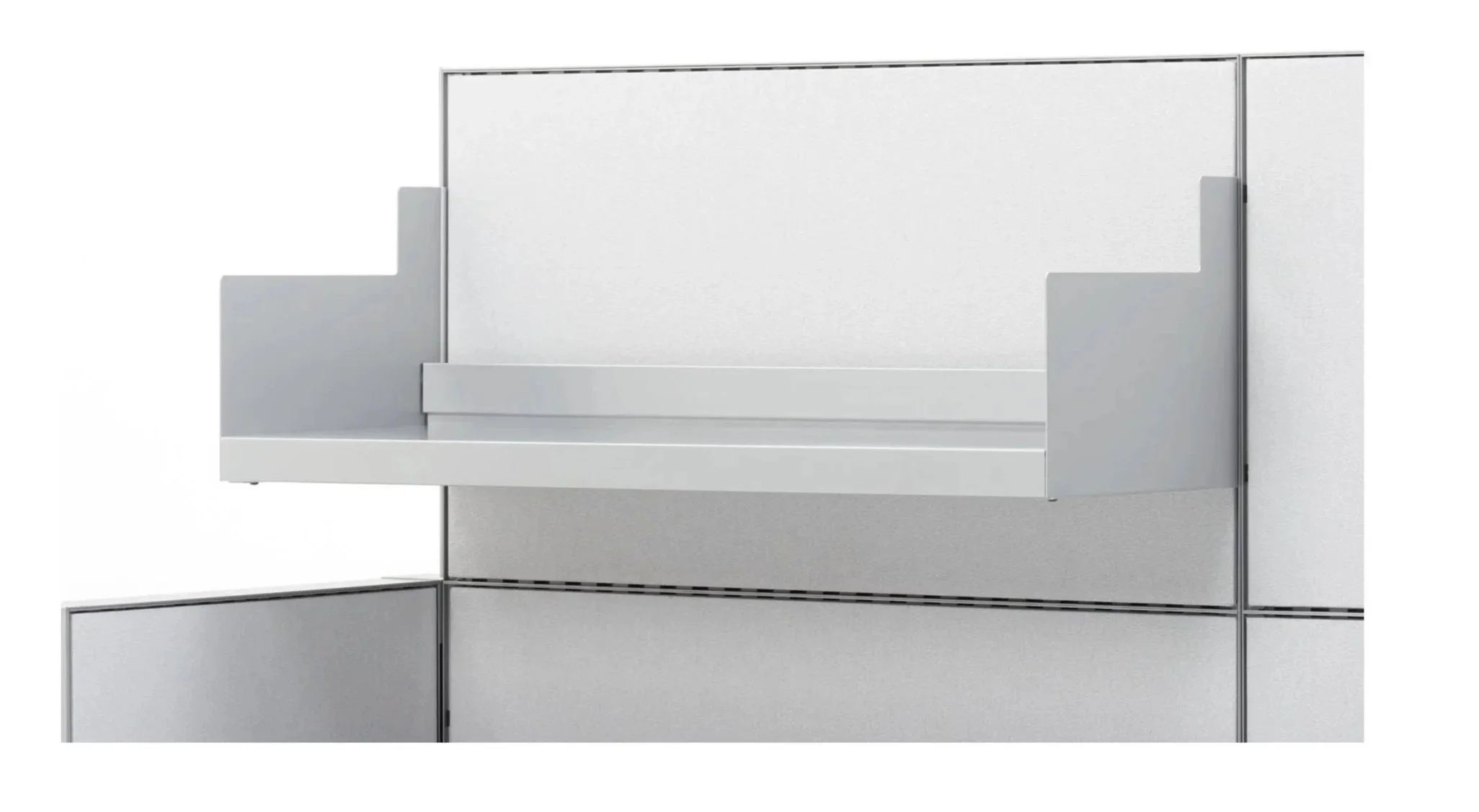

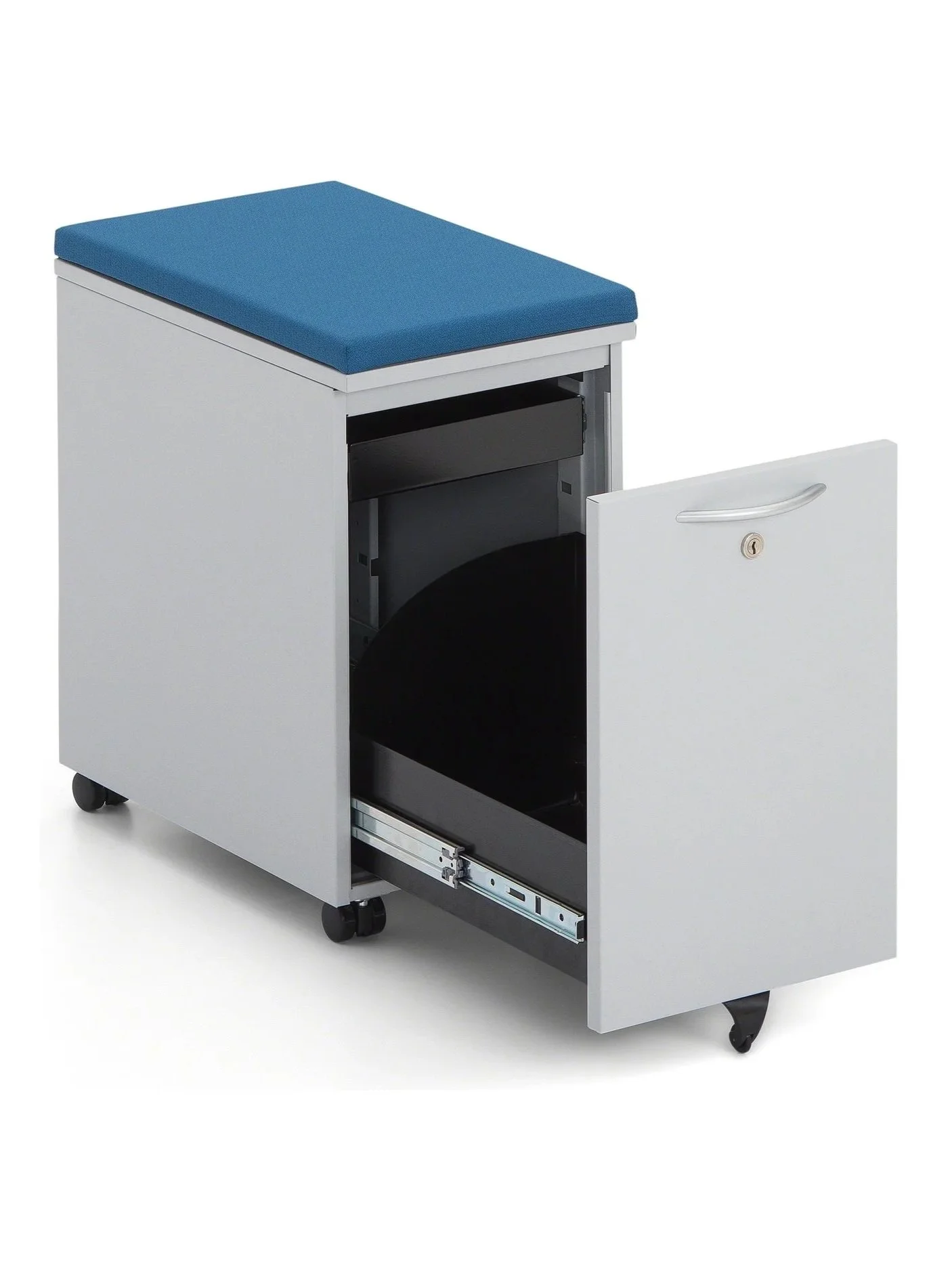

I’ve primarily worked on various steel storage products across different Steelcase brands. This includes refreshing existing products and creating new designs.

I’m also working on an innovative wood panel system solution that’s still being developed.

For more details about my current work, please reach out to me directly.

What have I learned?

Collaborating with design, marketing, and manufacturing teams has taught me how to balance cost, functionality, and user experience in real-world products.

I’ve created dozens of steel prototypes collaborating closely with Steelcase model makers, gaining up close insight into the fabrication and manufacturability of sheet metal.

Iterating and testing designs has shown me how to observe failures, learn from them, and refine concepts until they perform safely and reliably.

Visiting Steelcase plants and suppliers has given me insight into how products move through production, informing my design choices to improve manufacturability and reduce cost.